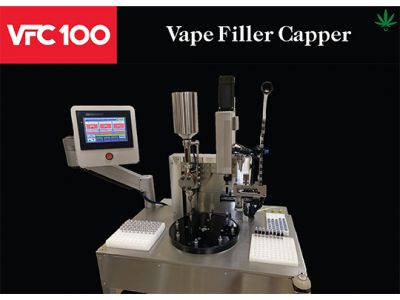

Vape Filler Capper - Simple Automation

The VFC 100 is vape cartridge filling and capping automation simplified. An ideal blend of filling and capping accuracy in a compact all electric package. Its dimensions are 30” L by 30” W x 36” H including production table which provides a portable work center for one operator. Standard heavy duty locking casters make this system flexible enough to produce anywhere you have 110-volt 1 phase electrical service. This is sanitary filling and capping in one effortless process.

The machine’s tank/hopper will accommodate sixty-four ounces of oil equal to approximately 1900 1 ML cartridges. The filler uses a proprietary fill nozzle. When filling the nozzle descends to the empty cartridge and seals on the glass. The system then evacuates all the oxygen within the empty cylinder. Next, the oil dispenses flowing equally in 360 degrees of the inside chamber. This filling method eliminates any unwanted air pockets and immediately primes the wick. The filled cartridge then automatically indexes to the capping station for closure, sealing out contaminants and eliminating leakers.

The VFC 100 was designed to operate at low temperatures. Depending on oil viscosity the machine will move the extract with little to no heat. No problems filling the most viscous live rosins and live resins. After the production run of one strain is complete cleaning is required when changing to a different oil. Simply pour 100 ML of Limonene into the tank/hopper and go to the cleaning cycle on the machine’s interface. The natural solvent moves automatically up and down through the machine and is dispensed to a holding tank for disposal at the end of the cycle. In addition, the inside of the tank will need to be wiped off with lint free soft cloth. The cleaning process can be accomplished in about 15-20 minutes.